Barcode Printing Solutions: Unlocking Manufacturing Potential in Industry 4.0 |

In the modern industrial world, driven by technology, competition, speed, and efficiency are the keys to success. Industrial plants, especially in the automotive and electronics manufacturing sectors, face challenges in managing complex production processes, controlling quality, and tracking a large number of parts. Therefore, the application of digital technology has become crucial in increasing efficiency, reducing costs, and enhancing competitiveness. |

In today’s technology-driven industrial world, competition, speed and efficiency are the keys to success. Industrial plants, especially in the automotive and electronics manufacturing sectors, face the challenge of managing complex production processes, controlling quality and tracking large numbers of parts. The application of digital technologies has become the key to increasing efficiency, reducing costs and enhancing competitiveness. |

|  |

Implementing barcode printing solutions not only improves production efficiency, but also improves quality, reduces costs, and creates a competitive advantage for industrial factories in the Industry 4.0 era that emphasizes connectivity, automation, and data analysis. |

|  |

To make barcode printing in industrial plants efficient, there are 4 main components required as follows:

Barcode Software  | Barcode Design and Management Software Software is the heart of creating, designing and managing barcodes to meet the standards and needs of the business. Good software should have the following features: - Create various types of barcodes (e.g. Code 128, QR Code)

- Connect to the database to retrieve data to create barcodes and save data

- Design labels as desired, such as adding logos, text

- Manage barcode data, such as editing, deleting, searching

- Support for use with other hardware, such as printers, readers

|

| Barcode Printer  | Barcode Printer Barcode printers are available in a variety of types depending on the workload, budget, and usage requirements, such as: - Desktop Printer: Suitable for low-volume printing

- Industrial Printer: Suitable for high-volume printing, durable

- Mobile Printer: Portable, suitable for field use

|

|

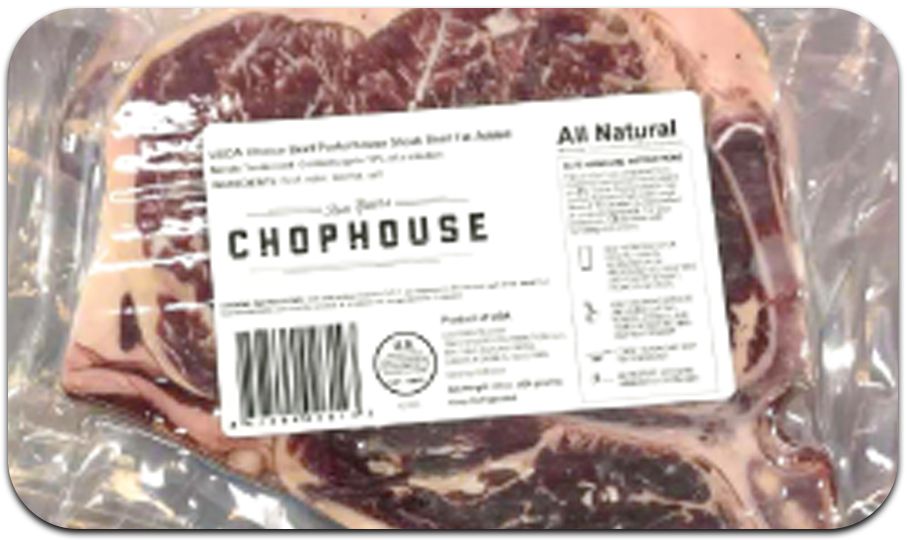

Consumables .jpg) | Consumables Consumables used in barcode printing are mainly divided into 3 types: - Barcode Labels: Available in various sizes, materials and adhesives

- Ribbons: Used in Thermal Transfer printers

- Ink: Used in Direct Thermal and Inkjet printers

|

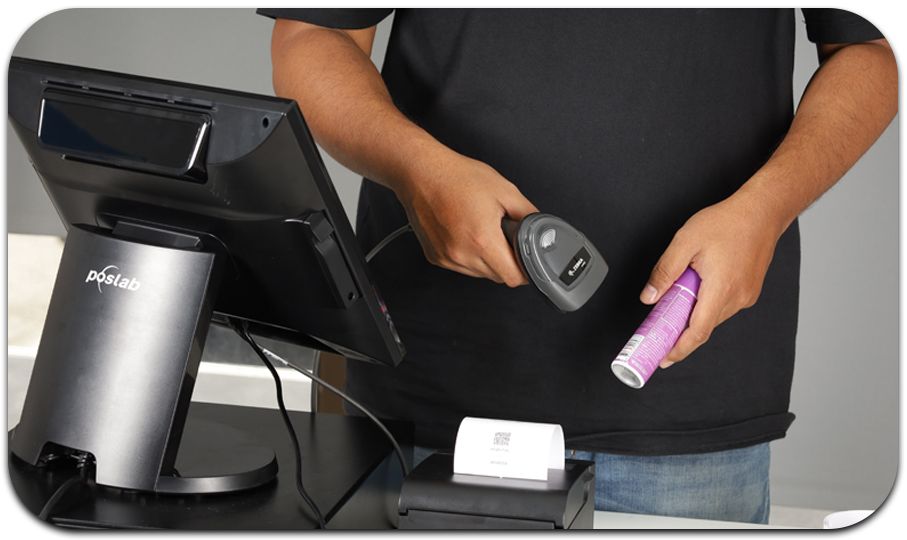

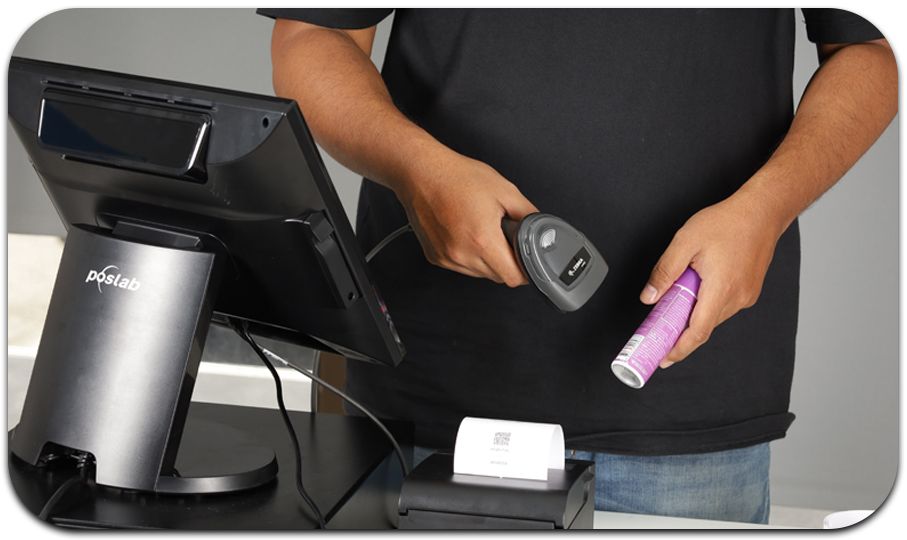

| เครื่องอ่านบาร์โค้ด (Barcode Scanner)  | Barcode Scanner Barcode readers are used to read data from barcodes. There are many types to choose from, such as: - Handheld Scanner: General use

- Presentation Scanner: Place on a table

- Embedded Scanner: Embedded in other devices, such as production lines

Choosing the right hardware and consumables will help make barcode printing efficient and cost-effective. |

|

Benefits of barcode printing solutions in industrial plants

Implementing barcode printing solutions in industrial plants can help increase efficiency, reduce costs, and enhance competitiveness in many areas, as follows:

| Inventory Management - Track Raw Materials: Barcodes help track raw materials from receipt to production process

- Inventory Control: Know the quantity and location of parts and finished goods

- Reduce Waste: Prevent loss and expired goods

- Increase Accuracy: Reduce errors in receiving, issuing and paying for goods

|

|

|

| Quality Control - Quality Assurance: Use barcodes to record data and verify part quality

- Defect Identification: Identify and track defective parts

- Data Analysis: Analyze data to improve manufacturing processes

- Cost Reduction: Reduce waste and rework

|

|

| Production Tracking - Track Progress: Track the status and progress of the work

- Identify Problems: Identify problem areas and bottlenecks

- Improve Efficiency: Improve the production process

- Reduce Lead Time: Reduce production lead times

|

|

| Asset Management - Identify Assets: Track and identify assets such as machinery, equipment

- Record Data: Record usage and maintenance data

- Improve Efficiency: Increase asset utilization efficiency

- Reduce Costs: Prevent loss and damage

|

|

| Error Reduction - Reduce errors: Reduce human errors such as data entry, picking

- Increase accuracy: Increase work accuracy

- Reduce costs: Reduce costs from errors

|

|

| Efficiency Improvement - Increase speed: Increase the speed of work

- Reduce time: Reduce the time of work

- Increase productivity: Increase productivity

- Reduce cost: Reduce operating costs

|

|

| System Integration - Data Link: Link data with other systems such as ERP, WMS

- Automation: Support automation

- Data Analysis: Analyze data to make decisions

|

|

Barcode printing solutions help industrial factories operate more efficiently, reduce costs and increase competitiveness in the Industry 4.0 era.

.jpg)